- Home

- About Us

Shenzhen South Source Core Electric Co. is a professional manufacturer focusing on design, R&D, production and marketing of glass and metal hermetic products. We can mainly produce various custom products such as glass to metal seals, ceramic to glass to metal seals etc. which can be widely used in various sealed containers. The seals produced by us can be used to provide power or transmit signal. They can satisfy our customers’ requirements on air tightness, resistance to pressure and insulativity. The main applications are various hermetic terminal, hermetic terminal plate, sensor connector and sight glass etc.

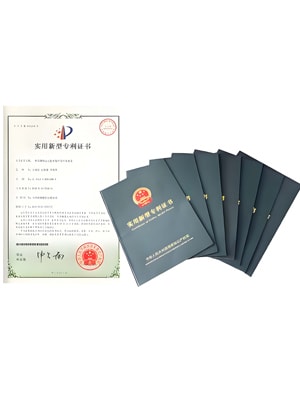

At SSC (south source core), we bring together a highly skilled team of researchers and managers with over 15 years of experience in the glass-to-metal sintering industry. Leveraging this expertise, we have secured 45 intellectual property certificates and patents related to advanced glass-to-metal sintering technologies and processes, including custom solutions and technical consulting.

Our production facilities are fully equipped with high-performance manufacturing and testing equipment, all independently developed by our in-house R&D team. We utilize controlled atmosphere furnaces capable of maintaining temperature accuracy within ±2°C and atmosphere variation within 3%, enabling precise thermal profiling, leak prevention, and excellent electrical performance.

Thanks to our rigorous process control, stable product quality, and exceptional cost-effectiveness, SSC has earned the trust of leading electric vehicle manufacturers such as BYD, Geely, Leapmotor, Li Auto, Valeo, Garrett Motion, and Seres. As of 2024, our products account for 54.8% market share in the EV compressor terminal segment in China.

Our facility includes dedicated workshops for raw material processing, sintering and assembly, hermeticity testing, resistance welding, fixture manufacturing, electrical performance testing, and electroplating. With a complete set of advanced equipment, we are committed to delivering high-quality products, fast turnaround times, and expert service tailored to your needs.

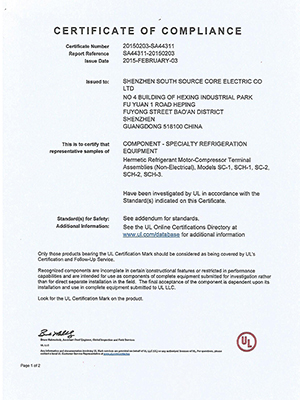

In March 2015, our products obtained UL certification for both the United States and Canada. By September 2016, we had achieved certification for the ISO/TS 16949 automotive quality management system, later upgraded to ISO/TS 16949:2016.

On January 11, 2024, we were further certified under the ISO 9001:2015 quality management system and the ISO 14001:2015 environmental management system.

We have proudly been recognized as a National High-Tech Enterprise for three consecutive terms and awarded the title of “Specialized and Innovative SME” in Shenzhen.

To date, we hold 45 patents and intellectual property certificates related to innovations in glass-to-metal sintering and packaging technology.

There are more than 1.5 million products on the market using our hermetic terminals. Our hermetic auto air conditioner terminals are designed exclusively for use in high efficiency vehicles. For example: BYD all models, BAIC all models, JiangHuai models, KingLong models, FAW-Volkswagen models and Foton models.

The ultra-high power hermetic terminal plate manufactured by South Source Core is used by a large-scale Dutch enterprise to improve the performance of its explosion-proof Bitzer compressor. Our customers' products are currently sold all around the world.

Our products are electrical safety components that are typically constructed from glass, metal, ceramics, and other materials. The core process is a high-temperature sintering method and product surface treatement. The advanateges of our products are listed below.

Good insulator: we make use of high purity heat resistance glass imported from the US. Our glass to metal sintering products have high insulating properties including the hermetic terminals, hermetic terminal plates and so on. Our factory inspection standard is strictly maintained at 100 thousand MΩ and above and is fully inspected under DC high voltage 1000V before shipping to customers.

High voltage resistance: Our factory inspection standard is strictly controlled at 3500V and above, current leakage less than 0.5mA and fully inspected before shipping our products.

Airtight: We use a CO atmosphere to protect the furnace. We control its sintering temperature and carbon potential graph in a strict manner to avoid air leakage. Besides, we use a self-developed air permeability tester to carry out 40kg stress tests to ensure the high air impermeability of each product.

Product surface treatment: Our hermetic terminals and terminal plates each undergo an advanced electroless nickel plating process. Our products are resistant to rust, corrosives, acid and alkali, and various refrigerants.