- Home

- Hermetic Products

- Glass-to-Metal Seals

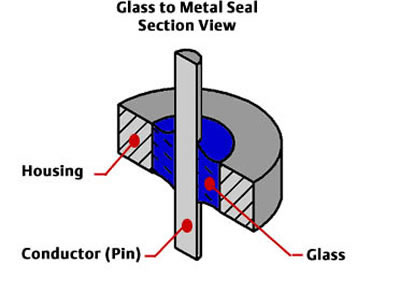

Glass-to-Metal Hermetic Seals

South Source Core provides various custom glass to metal hermetic seals, including seals providing power or transmitting signals in all sealed containers. The seals produced by us can mainly satisfy the requirements on air tightness, resistance to pressure and insulativity.

Applications

The glass to metal hermetic seals are mainly applied in sealed containers as power input accessory for motor and some other parts requiring power. They can also be used for signal transmission under high pressure and extreme temperature in the sealed container. The glass to metal hermetic seal features good air tightness, good insulation, good resistance to high pressure, good resistance to extreme temperature and some other advantages. The normal applications are hermetic terminals on refrigerator and compressor of air conditioner, hermetic terminal plates on commercial air conditioner, sensor connector, sight glass etc.

Customization

South Source Core can design proper products for our customers according to the specific requirements of them such as magnitude of the conduction current, magnitude of applied voltage, application environment, installation size etc.

Manufacturing material

The materials adopted to produce glass to metal hermetic seals are usually decided according to the custom requirements of our customers. The expansion factors of the selected glass and metal materials are carefully matched so that there will not be performance degradation of the metal material after sintering. The metal still features the following advantages: good elasticity, plasticity, rigidity, aging sensitivity, intensity, hardness, impact toughness, fatigue strength and fracture toughness etc.

Glass material: high temperature and superior glass insulator from U.S.A and Japan;

Metal material: carbon steel, stainless steel, Kovar alloy, 52 alloy, 4J28.

The glass to metal hermetic seals are mainly produced by compression seals technique. The expansion factor of glass and metal are not the same, so the contraction of the metal is larger than glass when cooling down during sealing in. So there will be compressive stress on glass from metal. Thus, the sealing in can be accomplished. The seals produced by this process feature good air tightness and electrical property.

The surface treatment of glass to metal hermetic seals adopts advanced electroless Ni plating process. The produced seals feature salt fog resistance which is over 48H. And there will be no peeling of plating during bending of the seals, so the glass will not be polluted. And the electrical property is quite good. The surface can also be treated by electroless silver or gold plating according to customers’ requirements.

Product performance- The product produced by South Source Core has the following performances:

- Air tightness: it can be up to 10-10 Pa.m3/s;

- Positive pressure bearing capacity: the seals can work normally under 4MPa pressure;

- Burst pressure: the seals can bear 20MPa burst pressure;

- Insulating property: according to static testing, the insulating property can be up to 10*104MΩ;

Core advantage:

- High insulation

South Source Core adopts heat resistant glass with high purity from U.S.A. so that the glass to metal hermetic seals produced by us feature ultra-good insulating property. The standard value of the finished products is strictly controlled and should be over 10*104MΩ. All the products will be inspected under DC, 1000V before shipment. - High voltage resistance

The products of South Source Core feature ultra-good high voltage resistance. The standard value is strictly controlled and should be over 3500V. And the leakage current should be lower than 0.5mA. All the products are inspected before shipment. - High air tightness

Our company adopts advanced sintering furnace which uses CO as the sintering atmosphere. Both the temperature curve and carbon potential curve of sintering are strictly controlled, thus ensuring that gas leakage will not happen on the products produced by this special process. Meanwhile, to ensure high air tightness, all the products will be inspected by automatic airtight inspection machine which is independently developed by us under 40 KG pressure. - Advanced surface treatment

The glass to metal hermetic seals produced by South Source Core adopts advanced electroless Ni plating process so that the products feature good corrosion resistance, acid-base resistance, rust protection, high temperature resistance, various coolants and refrigerating fluid resistance etc.

SHENZHEN SOUTH SOURCE CORE ELECTRIC CO.,LTD

Address: 6F8Block Huafeng hi-tech park Tangwei Fuhai street Bao'an district Shenzhen

Contact Person: Li Song

Contact Number: +86-13699892812

Tel.: +86-755-29918396

Fax: +86-755-29919116

Email: ssc@sscore.net

WhatsApp: +86-13699892812